Connect to PLC ( Ethernet/IP, PROFINET)

This guide shows you how to connect your OV80i camera to industrial PLCs using EtherNet/IP or PROFINET protocols. These connections enable real-time communication for triggering inspections, receiving results, and integrating vision inspection into your automated production systems.

When to Use PLC Communication: When you need to integrate vision inspection with automated production lines, trigger inspections from PLC signals, send pass/fail results to PLCs, or coordinate vision inspection with other automation equipment.

Prerequisites

- OV80i camera system set up and connected to network

- PLC system with EtherNet/IP or PROFINET capability

- Network infrastructure connecting camera and PLC

- Access to PLC programming software (Studio 5000, TIA Portal, etc.)

- Basic understanding of industrial networking concepts

Understanding PLC Communication Protocols

EtherNet/IP

- Used by: Allen-Bradley/Rockwell Automation PLCs primarily

- Benefits: High-speed communication, widely supported, explicit and implicit messaging

- Applications: ControlLogix, CompactLogix, and other Rockwell platforms

- Data Exchange: Cyclic I/O and message-based communication

PROFINET

- Used by: Siemens and other European manufacturers

- Benefits: Real-time deterministic communication, advanced diagnostics

- Applications: Siemens S7 PLCs, various industrial automation systems

- Data Exchange: Cyclic I/O with real-time performance

Part 1: EtherNet/IP Connection

Step 1: Configure OV80i for EtherNet/IP

1.1 Access Industrial Ethernet Settings

- Open the OV80i web interface

- Navigate to "Industrial Ethernet" in the left menu

- You'll see the Industrial Ethernet configuration page

1.2 Enable EtherNet/IP Protocol

- In the Industrial Ethernet menu, select "EtherNet/IP" protocol

- Click "Enable" to activate EtherNet/IP communication

- Note your camera's network settings in the Device Information window

1.3 Configure Network Settings

- Set Static IP Address (recommended for production)

- Go to System Settings > Network

- Configure static IP in same subnet as your PLC

- Example: Camera: 192.168.1.100, PLC: 192.168.1.50

- Configure Subnet Mask (typically 255.255.255.0)

- Set Gateway if required for your network

1.4 Configure EtherNet/IP Device Settings

- Device Name: Set a meaningful name for your camera

- Assembly Configuration: Configure input/output data structures

- Connection Parameters: Set appropriate timeout and RPI (Requested Packet Interval) values

- Click "Save" to apply EtherNet/IP settings

Step 2: Configure PLC Recipe Settings

2.1 Enable PLC Triggering (Optional)

- Navigate to Recipe Editor > Imaging Setup

- In Photometric Control, set Trigger Mode to "PLC Trigger"

- Important: Once PLC Trigger is enabled, manual triggering is disabled

2.2 Configure Pass/Fail Output

- Navigate to Recipe Editor > IO Block

- Ensure your inspection logic ends with "Final Pass/Fail" node

- This sets the Inspection Pass bit in the EtherNet/IP assembly

Step 3: Configure PLC Side (Allen-Bradley Example)

3.1 Install EDS File

- Download EDS file from Overview.ai support or camera interface

- In Studio 5000, go to Tools > EDS Hardware Installation Tool

- Browse and select the OV80i EDS file

- Follow the installation wizard to complete EDS installation

3.2 Add OV80i Module to PLC Project

- In Studio 5000, open your PLC project

- Go to I/O Configuration in the project tree

- Right-click on Ethernet module and select "New Module"

- Search for "OV80i" or "Overview" in the module catalog

- Select the OV80i module and click "Create"

3.3 Configure Module Properties

- Name: Enter descriptive name for the camera

- IP Address: Enter the OV80i's IP address (e.g., 192.168.1.100)

- RPI (Requested Packet Interval): Set to 100ms or as required

- Connection Parameters: Configure input/output data sizes

- Click "OK" to create the module

3.4 Map I/O Data

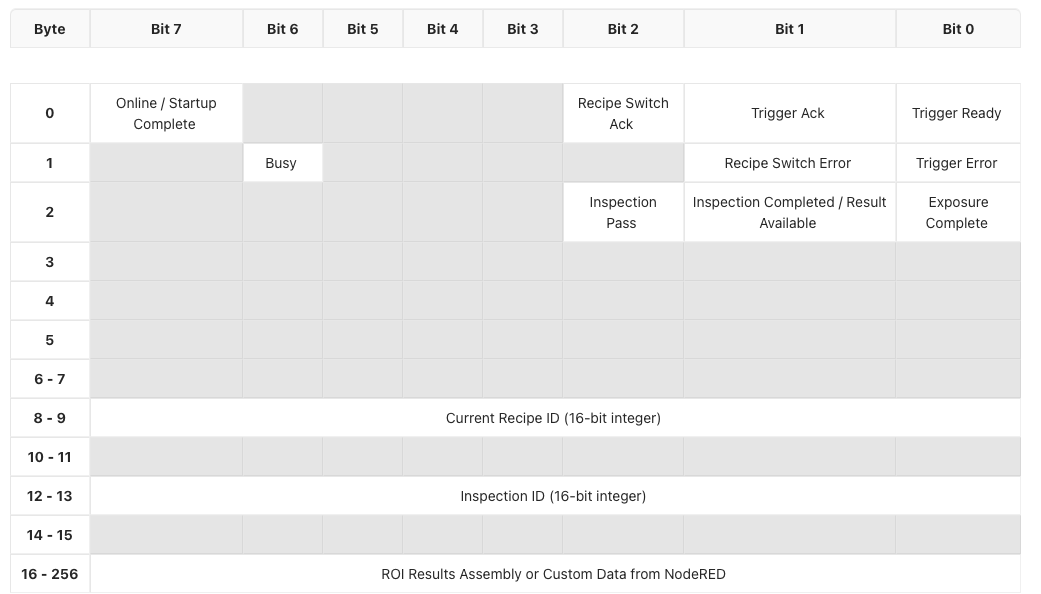

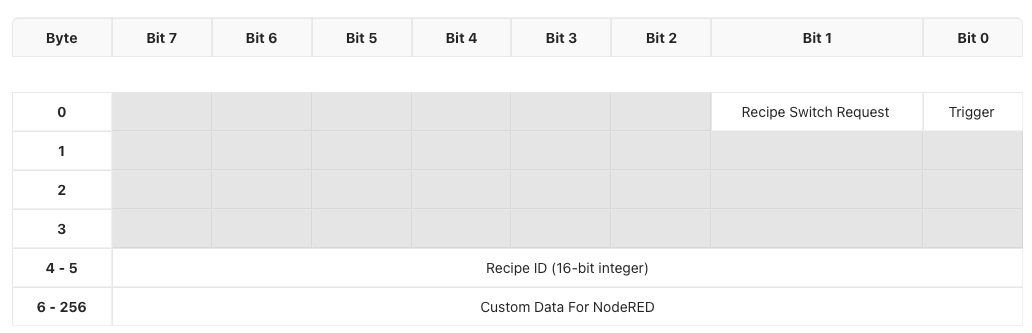

- Input Data: Inspection results, status bits, camera ready signals

- Output Data: Trigger commands, recipe change requests, control signals

- Create tags in your PLC program to map to the I/O data

- Example Input Tags:

Camera_InspectionPass: BOOLCamera_Ready: BOOLCamera_Busy: BOOL

- Example Output Tags:

Camera_Trigger: BOOLCamera_RecipeSelect: INT

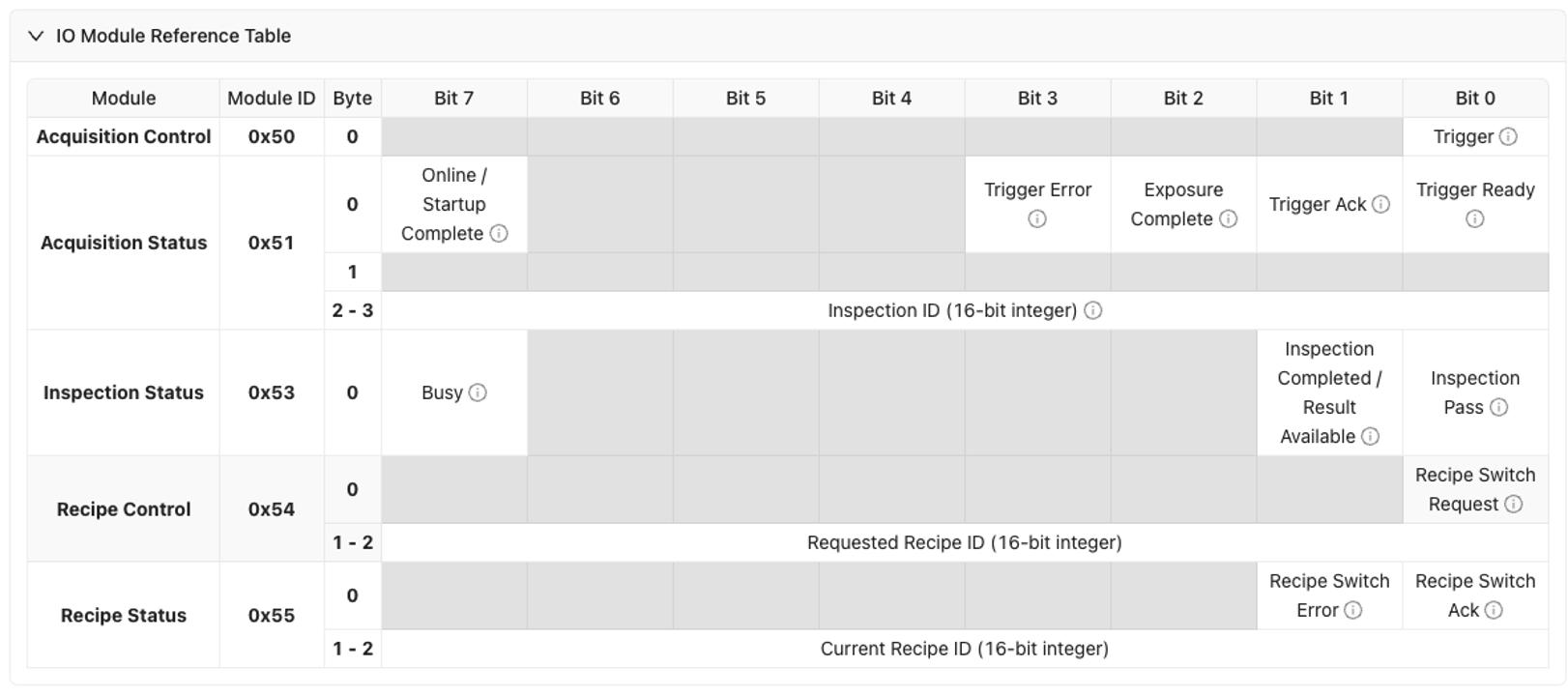

Input Assembly (OV80i → PLC)

Output Assembly (PLC → OV80i)

Step 4: Test EtherNet/IP Communication

4.1 Verify Connection Status

- In Studio 5000, check module status in I/O Configuration

- Green checkmark indicates successful connection

- Red X indicates communication issues

4.2 Test Basic Communication

- Monitor input data from camera in PLC program

- Toggle output signals to camera and verify response

- Check diagnostic information for any error codes

4.3 Test Trigger and Response

- Enable PLC trigger output to camera

- Monitor inspection results in PLC input data

- Verify pass/fail status updates correctly

- Check timing of trigger and response cycles

Part 2: PROFINET Connection

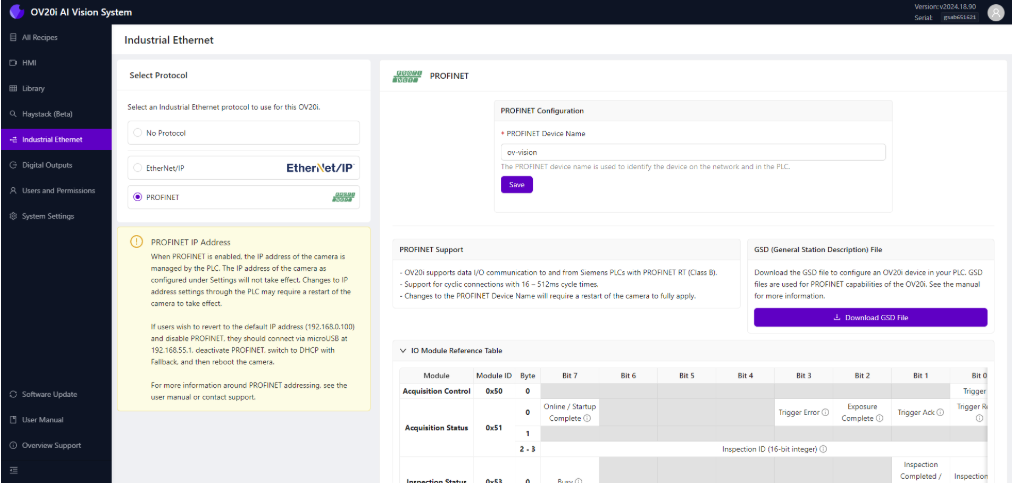

Step 1: Configure OV80i for PROFINET

1.1 Access Industrial Ethernet Settings

- Open the OV80i web interface

- Navigate to "Industrial Ethernet" in the left menu

- Select "PROFINET" protocol from the options

1.2 Enable PROFINET Protocol

- Click "Enable PROFINET" to activate protocol

- Note: PROFINET manages camera IP address when enabled

- Camera IP settings may be overridden by PLC configuration

1.3 Configure PROFINET Device Settings

- PROFINET Device Name: Set unique name for camera

- Example: "OV80i_Line1_Station2"

- Must be unique if multiple cameras on same PLC

- Device Configuration: Note the device capabilities and data structure

- Click "Save" to apply PROFINET settings

Step 2: Configure PLC Recipe Settings

2.1 Enable PLC Triggering (Optional)

- Navigate to Recipe Editor > Imaging Setup

- Set Trigger Mode to "PLC Trigger" if needed

- Warning: Manual triggering disabled when PLC trigger is active

2.2 Configure Pass/Fail Logic

- Navigate to Recipe Editor > IO Block

- Ensure inspection logic concludes with "Final Pass/Fail" node

- This sets the Inspection Pass bit in PROFINET input assembly

Step 3: Configure PLC Side (Siemens Example)

3.1 Install GSDML File

- Download GSDML file from Overview.ai support

- In TIA Portal, go to Options > Manage general station description files (GSD)

- Click "Install GSD file" and select the OV80i GSDML file

- Complete the installation process

3.2 Add OV80i to Hardware Configuration

- In TIA Portal, open Device & Networks view

- From the Hardware catalog, expand Other field devices > PROFINET IO

- Locate OV80i device and drag it to the network view

- Connect the OV80i to your PLC's PROFINET interface

3.3 Configure Device Properties

- Device Name: Set same name as configured in camera

- IP Address: Configure IP address (may be managed by PLC)

- Update Time: Set cycle time (default 128ms recommended)

- I/O Data: Configure input/output data modules as needed

3.4 Assign IP Address and Device Name

- Compile hardware configuration

- Go online with PLC

- Assign IP address to OV80i device

- Assign device name matching camera configuration

Step 4: Test PROFINET Communication

4.1 Verify Device Status

- In TIA Portal, check device status in Device & Networks

- Green status indicates successful communication

- Red status indicates communication problems

4.2 Test Data Exchange

- Monitor input data from camera in PLC program

- Control output data to camera and verify response

- Check diagnostic buffers for any error messages

4.3 Test Inspection Cycle

- Activate PLC trigger to camera

- Monitor inspection results in PLC input data

- Verify pass/fail status transmission

- Check cycle timing meets application requirements

Step 5: Troubleshooting PLC Communication

5.1 Common EtherNet/IP Issues

| Problem | Symptoms | Solution |

|---|---|---|

| Connection timeout | Module shows red X in Studio 5000 | Check IP addresses, network connectivity, firewall settings |

| Data not updating | I/O data remains static | Verify EDS file version, check assembly configuration |

| Trigger not working | Camera doesn't respond to PLC trigger | Check trigger bit mapping, verify PLC output is active |

| Slow response | Delayed inspection results | Adjust RPI timing, check network load |

5.2 Common PROFINET Issues

| Problem | Symptoms | Solution |

|---|---|---|

| Device not found | Camera not visible in TIA Portal | Check GSDML file installation, verify device name |

| IP address conflicts | Communication errors | Ensure unique IP addresses, check subnet configuration |

| Cycle time errors | Watchdog timeouts | Increase cycle time, check network performance |

| Data format errors | Incorrect I/O data | Verify GSDML version, check data structure mapping |

5.3 Network Diagnostics

- Ping test between camera and PLC

- Check network switches and cable integrity

- Monitor network traffic for bandwidth issues

- Verify firewall settings don't block communication

Step 6: Performance Optimization

6.1 Timing Considerations

- EtherNet/IP RPI: Start with 100ms, adjust based on application needs

- PROFINET Cycle Time: Use 128ms default, reduce only if required

- Inspection Time: Consider total inspection time in cycle planning

- Network Latency: Account for network delays in timing calculations

6.2 Data Efficiency

- Minimize data size in I/O assemblies

- Use appropriate data types (BOOL vs INT vs REAL)

- Avoid unnecessary data in cyclic communication

- Use explicit messaging for non-critical data

6.3 Network Management

- Use managed switches for better diagnostics

- Implement redundancy for critical applications

- Monitor network utilization to prevent congestion

- Plan IP address ranges for scalability

Success! Your PLC Communication is Established

Your OV80i camera can now:

✅ Communicate with PLCs using industrial protocols

✅ Receive trigger signals from automation systems

✅ Send inspection results to PLC control logic

✅ Integrate seamlessly with production line automation

✅ Support remote recipe changes and system coordination

Best Practices

Production Deployment

- Use static IP addresses for consistent communication

- Document all network settings and device configurations

- Test thoroughly before production deployment

- Plan for maintenance and troubleshooting procedures

Security Considerations

- Segment industrial networks from office networks

- Use managed switches with appropriate security features

- Monitor network access and device communications

- Keep firmware updated on all network devices

Maintenance

- Regular network health checks and diagnostics

- Monitor communication statistics for performance trends

- Update device drivers and configuration files as needed

- Maintain documentation of all network configurations

Next Steps

After establishing PLC communication:

- Develop PLC control logic for your specific application

- Create operator interfaces for monitoring and control

- Set up data logging for production tracking

- Implement alarm handling for system fault management

- Plan system backup and disaster recovery procedures

📥 Download Files

Download these essential files for PLC integration (compatible with both OV20i and OV80i systems):

EtherNet/IP Configuration

- OV80i EDS File - Electronic Data Sheet for Allen-Bradley Studio 5000

- Required for configuring OV80i module in ControlLogix/CompactLogix systems

PROFINET Configuration

- OV80i GSDML File - Device description for Siemens TIA Portal

- Required for configuring OV80i device in PROFINET networks

Sample PLC Code (Universal)

-

Recipe Switch Routine - Ladder logic for recipe switching

- Complete Allen-Bradley routine for changing camera recipes via PLC

- Works with both OV20i and OV80i systems

-

Camera Trigger Routine - Ladder logic for triggering inspections

- Complete Allen-Bradley routine for triggering camera and handling results

- Works with both OV20i and OV80i systems

File Usage Notes:

- EDS Files: Import into Studio 5000 via Tools → EDS Hardware Installation Tool

- GSDML Files: Import into TIA Portal via Options → Manage GSD Files

- L5X Files: Import ladder logic directly into your Allen-Bradley project

- Camera-Specific: Use OV80i EDS/GSDML files for OV80i systems, sample code is compatible across models

Related Documentation

- Reference: EtherNet/IP Assembly Maps & Timing Diagrams

- Reference: PROFINET GSDML & Network Limits

- How-To: Digital Input Trigger Setup

- How-To: System Settings (Network/Time/Logs)

- Troubleshooting: Camera to PLC Communication Fails